The Difficulties in Writing Specifications for Millimeter-Wave Components

Introduction

We often accept a manufacturer’s specification of their millimeter wave components without a second thought. But a survey of the industry will reveal that what one manufacturer means by, for example, “20 dB isolation” could be a very different standard of performance from another manufacturer who makes the same claim. This is partially because of inherent difficulties in specifying component performance over broad bandwidths. But there are additional unique difficulties at the higher mm-wave frequencies. S-parameter measurements from mm-wave isolators will be used as an example to demonstrate some of these challenges. When it comes to, for example, insertion loss and isolation, even a well written specification may have limited use because of these challenges and test data may be required for perfect clarity.

The Difficulty

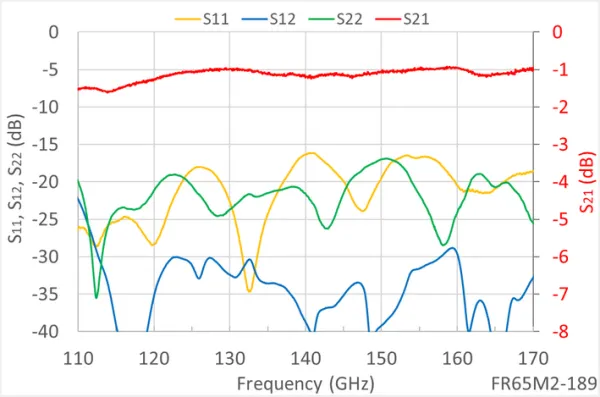

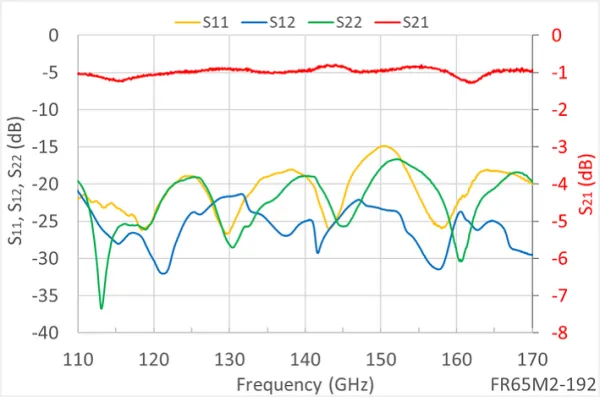

Because millimeter-wave isolators (30–400 GHz) are fabricated using extremely small parts, they are very sensitive to fabrication and alignment errors. The variations between components cause each component to have its own unique signature—especially for performance characteristics such as isolation which can vary significantly between components. Due to the difficulty of finding a helpful quantifiable summary statistic, the industry lacks standards and has mostly relied on the pragmatic methodology of specifying “typical” performance for insertion loss, isolation, and VSWR. For example, consider the 2-port s-parameter measurements of two different D-band isolators from Micro Harmonics below.

How would you characterize the performance of the D-band isolators? More specifically, what are the insertion loss (red), reflections (yellow and green), or isolation (blue)? Is the isolation for the first isolator 22 dB or 30 dB? These are questions about the performance statistics of the isolators. To answer these questions effectively, one needs to find helpful summary statistics to characterize thousands of data points.

To be helpful, these statistics should:

- Summarize the performance across the whole band of an isolator.

- Be useful for comparing the performance between isolators.

- Ultimately characterize the performance of an entire product line.

The lack of rigorously defined summary statistics—though convenient for manufacturers—creates difficulties for engineers and purchasers who are trying to:

- Understand the performance of the components they purchase.

- Compare mm-wave components among different manufacturers.

The Limitations of the Industry Status Quo

Most manufacturers specify a “typical” or a “typical max/min”. Since the term “typical” has no standard mathematical definition, it can be defined to mean almost anything. For instance, “typical” could be defined in terms of test data from a batch of 50 W-band isolators as follows: Each isolator is tested at 10 frequencies across the band from 75-110 GHz. Half of the tested isolators have an insertion loss of less than 2 dB at 3 or more frequencies in the band. The whole batch of isolators could be rated as having a typical insertion loss of 2 dB. That means that a large number of isolators in that batch may have an insertion loss greater than 2 dB across the entire band and yet the specification is deemed to have been met. There is often an assumption that typical means most of the data for my isolator when in fact it may mean none of the data for your particular isolator.

Even if you did know what a manufacturer meant by typical, it is unlikely that the definitions between two manufacturers will be the same or even similar. Therefore, one manufacturer will be stricter, and another manufacturer will be more liberal in their respective specification methodologies, rendering a comparison of each manufacturer’s specifications misleading. The problem is not that a given manufacturer specs “wrongly” (though a manufacturer could spec in a misleading manner), but that the lack of consistency and standardization is unhelpful and impedes someone trying to perform a reliable analysis.

Even if there were specification standards, specifications still have their inherent limitations. Millimeter-wave components often have inconsistent performance signatures between like components due to material and assembly variations. This makes the task of finding one number that helpfully represents the isolation at every frequency for every manufactured component difficult.

With the variation among mm-wave components, the inherent limitations of specifications, and the lack of industry standards, the best practice would be to test every purchased component. However, most users don’t have access to the test equipment needed to verify the operation of mm-wave components. This leaves the engineers with no choice but to accept the ambiguities and limitations of the manufacturer’s specification.

Micro Harmonic’s Response

Micro Harmonics has rigorously defined specifications in an effort to provide the most helpful summary statistics. Additionally, we have invested heavily in vector network analyzers and frequency extenders. We provide comprehensive test data for every unit we sell by testing over 1000 points across the band. This practice ensures that we maintain high standards of performance and that our customers know precisely what they are purchasing. It is highly advisable to obtain test data from the manufacturer when purchasing mm-wave components, particularly for components at the higher millimeter-wave frequencies (> 90 GHz). The only surefire way to know what you are getting is to test the component at many points across the band. Welcome to the world of mm-wave components. If you have any questions, feel free to contact us!